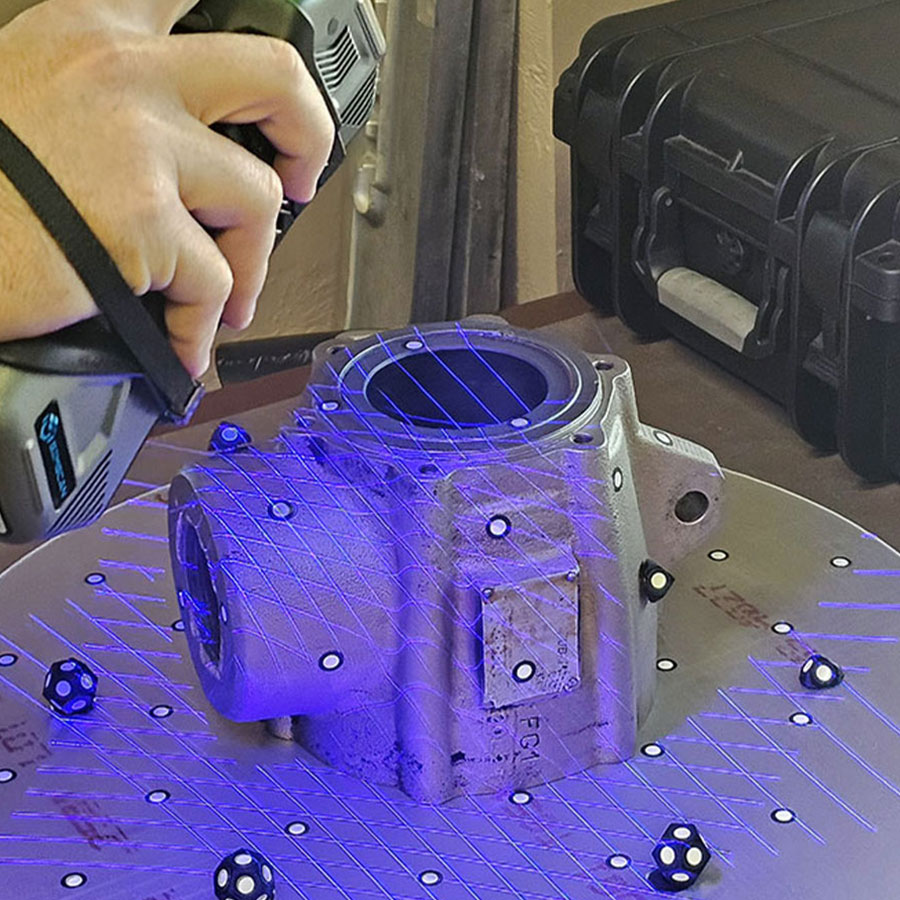

Aerospace Contractors, & Defense Contractors

Our customers include aerospace and defense contractors, military programs, and government agencies that rely on precision, capacity, and compliance.

Precision Fiber

Laser Cutting

Our fiber laser cutting operation combines speed, accuracy, and consistency to support demanding production requirements.

Die Design &

Manufacturing

Our die design and manufacturing capabilities support precision tooling for prototype, short-run, and production applications.