Equipment List

Explore Our Equipment to see what we can handle

Why we are listing our equipment? We use over 120 machines for production, in a 160,000 sq ft facility. Our shop has the equipment to help fix almost any related problem. This list will help give you an idea of the specifications of our machines, for you to better understand our abilities. Looking for a custom job? Get a Quote today!

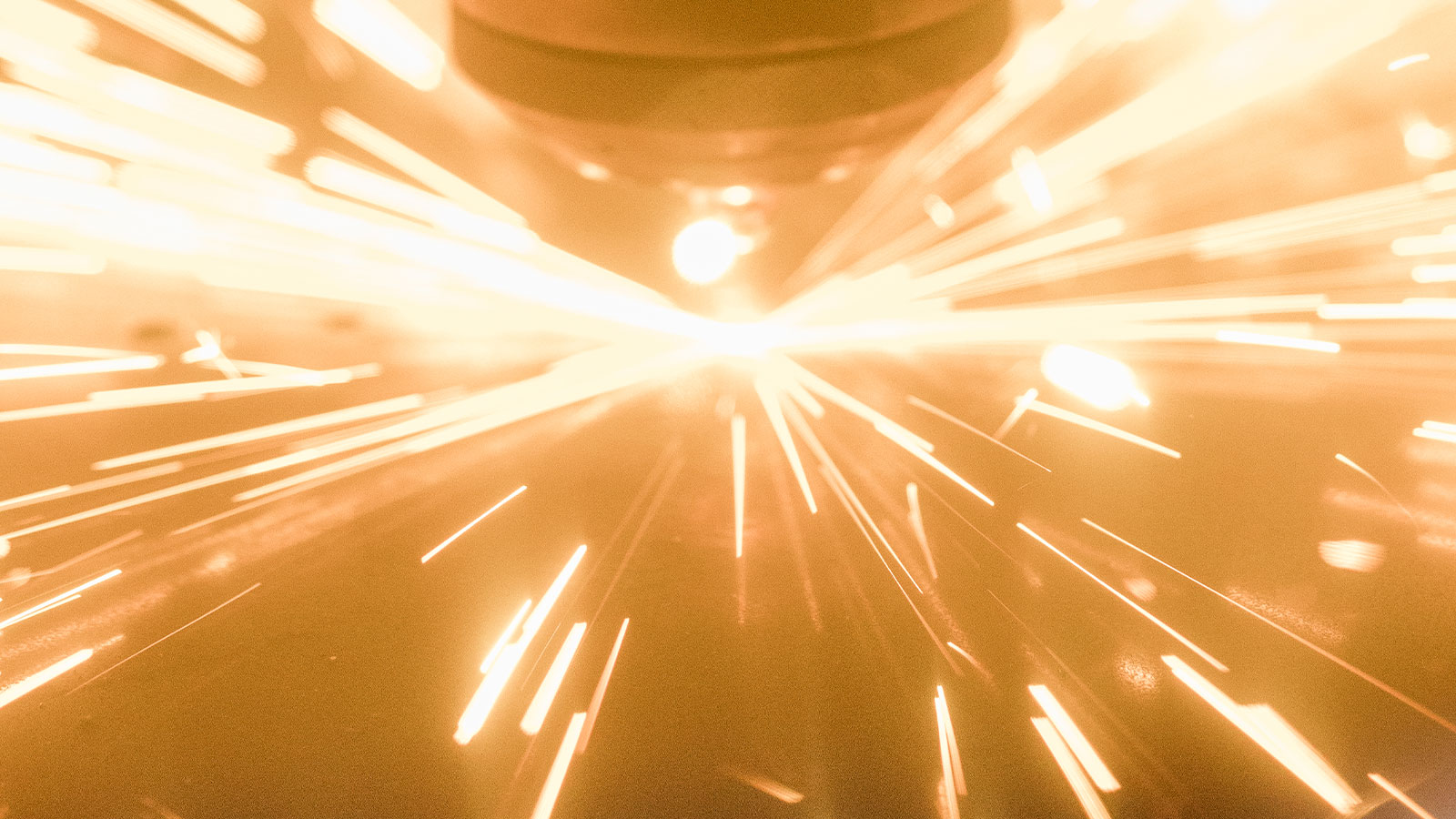

Laser:

Amada Ensis 3015 AJ 6K Fiber Laser (60” X 120” table)

Amada LCG 3015 AJ 6K Fiber Laser (60” X 120” table)

Amada Ensis 3015 AJ 9K Fiber Laser (60” X 120” table)

Amada Ensis 4020 AJ 9K Fiber Laser (80” X 160” table)

Amada Ensis 4020 AJ 9K Fiber Laser (60” X 120” table)

Amada Ensis 4020 AJ 12K Fiber Laser (60” X 120” table)

Form:

Accurpress Accell 417510 (175 Ton, 10ft)

Accurpress Accell 425012 (250 Ton, 12ft)

Accurpress Accell 425010 (250 Ton, 10ft)

Welding:

Miller CP-302

Miller Deltaweld 452

Miller Millermatic 350p

Miller Deltaweld 302

Miller Dynasty 280

Daihen DP 400 Aluminum Welder

Hypertherm Powermax 1650 Plasma Cutter

(2) 4’ X 8’ Strong Hand Weld table

Waterjet:

Omax 60120 (60” X 120” table, Cut any material up 6” thick)

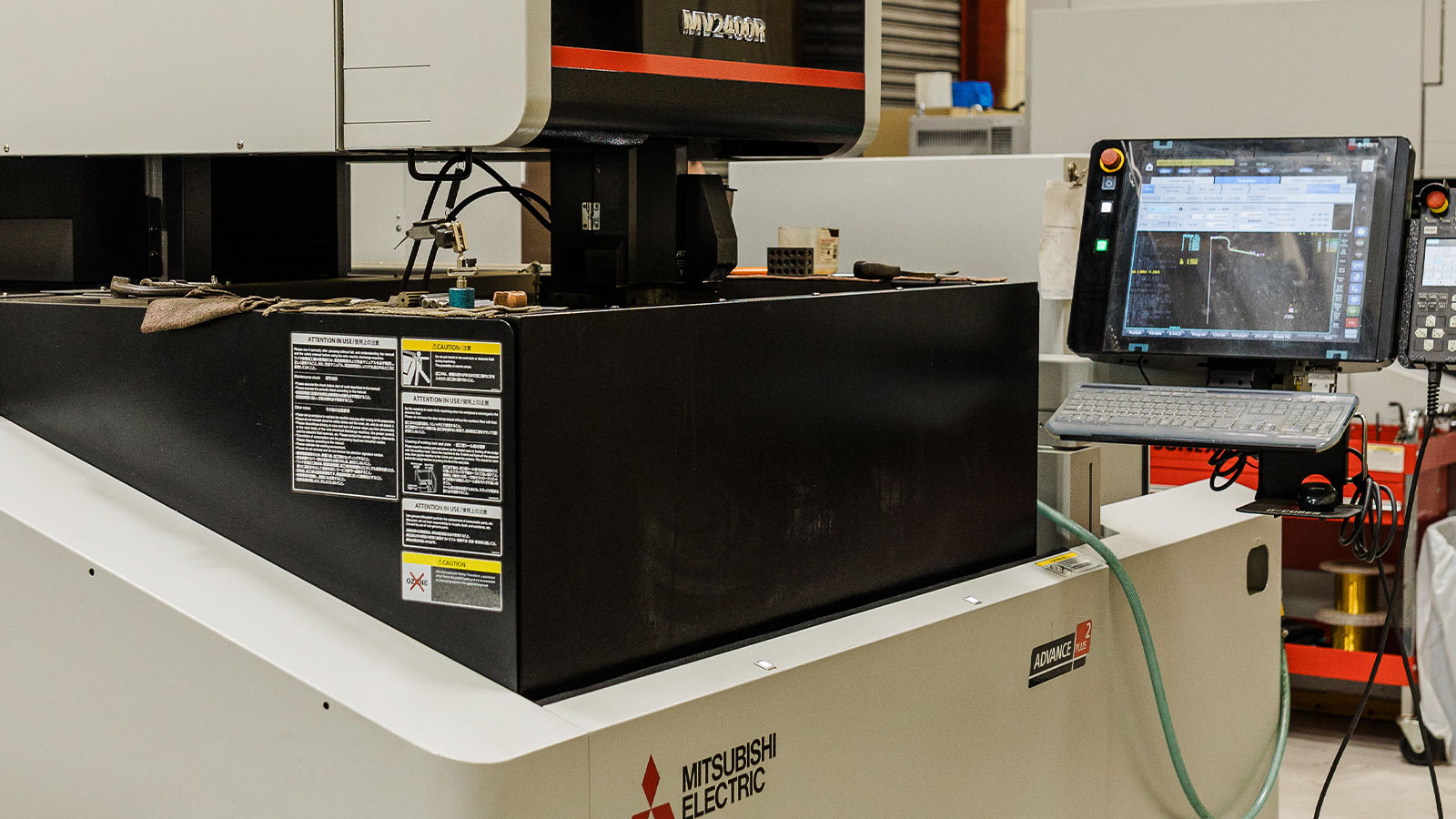

EDM:

(4) Mitsubishi MV2400R

Agie CNC Drilling

Mitsubishi M25K

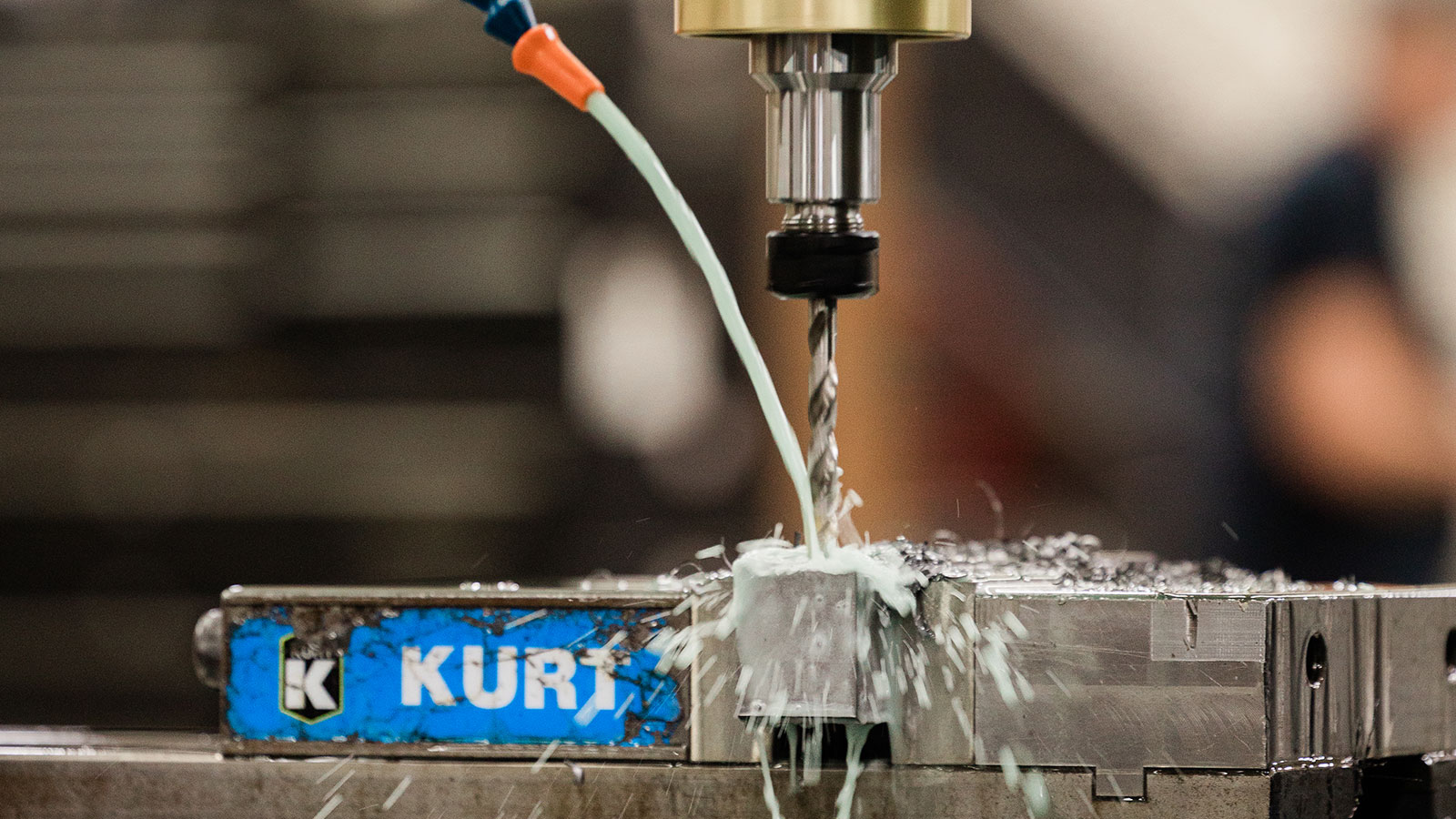

CNC Milling:

(6) Okuma Genos M560-V (41.34” x 22.05” x 18.11” Max machining volume, 1,980 lbs table capacity, (1) 5-axis milling capabilities)

Okuma M560-V vertical mill

Okuma Millac 1052V (80.71” x 41.73” x 31.50” of travel, 5,511 Max table load)

Mori Seiki MV-80 (80” x 32.05” x 29.53” of travel, 6,600 lbs max table load)

Toshiba BP-110.P20 Boring Mill, (100” (X), 65” (Y), 45” (Z), 20” (W), 40,000 lbs max table load)

CNC Turning:

(2) Okuma MULTUS U3000 9-axis turning center

Okuma MULTUS B300II

Okuma LB 35 II

Okuma LB3000 EX III

Okuma Genos L300E-M

Okuma Captain L470

Okuma Captain 70

Okuma Captain L370M

Okuma Cadet L1420

(3) Mazak Quick Turn Nexus 450-II MY (12.3” (X), 124.8” (Z), 116.14” (W) Max Swing 33.27”)

Stamping:

Komatsu E2G400U (440 Ton, 49” x 99” Bolster, Perfect Feeder)

DEES Hydraulic (400 Ton, 47” x 137” Bolster)

Komatsu OBW200 (220 Ton, 33.5” x 95” Bolster, Minster Feeder)

Stamtec G1-110 (121 Ton, 23.6” x 45.25” Bolster, CWP Feeder)

Seyi Mark 2-121-W (121 Ton, 26.8” x 45.3” Bolster)

AIDA 80 (88 Ton, 18.1" x 37.4" Bolster)

Clearing Niagara (440 Ton 54" x 96" Bolster)

Air-Hydraulics 50 (50 Ton)

Press Master (50 Ton Hydraulic)

Surface Grinding:

Blanchard Grinder (120" Corner to corner, 48" height, & 15,000lbs capacity)

Okamoto 16-32

(2) Okamoto ACC 6-18 DX3

Okamoto 6-18

(2) Okamoto ACC 12-24GX

Manual Machining:

Trax DPM5 (CNC controls)

(5) Acer E-mill

Lagun Knee Mill

Brown & Sharpe No. 3B Plain

Clausing-Metosa C2087SS Lathe

Clausing-Metosa C1565VS Lathe

Harding Tool Room Lathe

(2) Sharp RD-1600 Radial Arm Drill

Ikeda Radial Arm Drill

(2) Clausing 20 Drill Press

Part Prep:

(2) Sweco FMD-3LR Vibratory Tumbler

Do ALL C-916 Saw

Crob Band Saw

Marvel Series 8 Mark III Band Saw

Sand Blast Cabinet

Parts Cleaning Tub

(4) pedestal Grinders

(2) Disk Grinders

Jet 6”x48” & 12” Disk Machine

Drill Presses:

(2) Sharp RD-1600 (16” Column, 4’ Arm)

Ikeda RM-1000 (10” Column, 3’ Arm)

(2) Clausing 20

Heat Treat:

(3) Cress Heat Treat Ovens

Gruenberg Oven

Rockwell Hardness Tester

Marking:

Keyence 50-Watt fiber marking/engraving laser

Miscellaneous:

Bambu labs H2D Pro 3D Printer

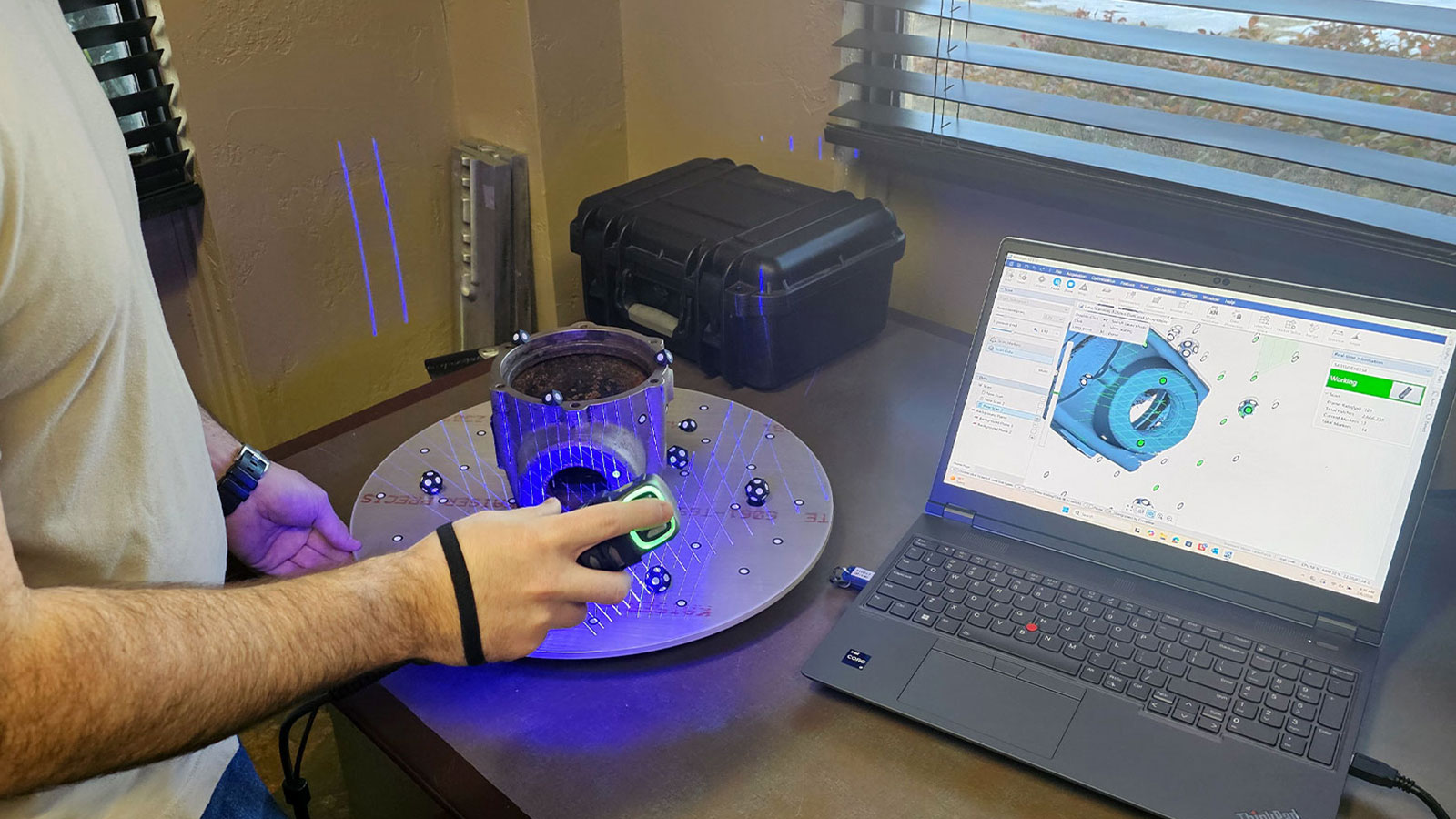

SIMSCAN Handheld 3D Scanner

(3) Sullair 3700 Compressors

Brecknell 10,000 lbs Scale

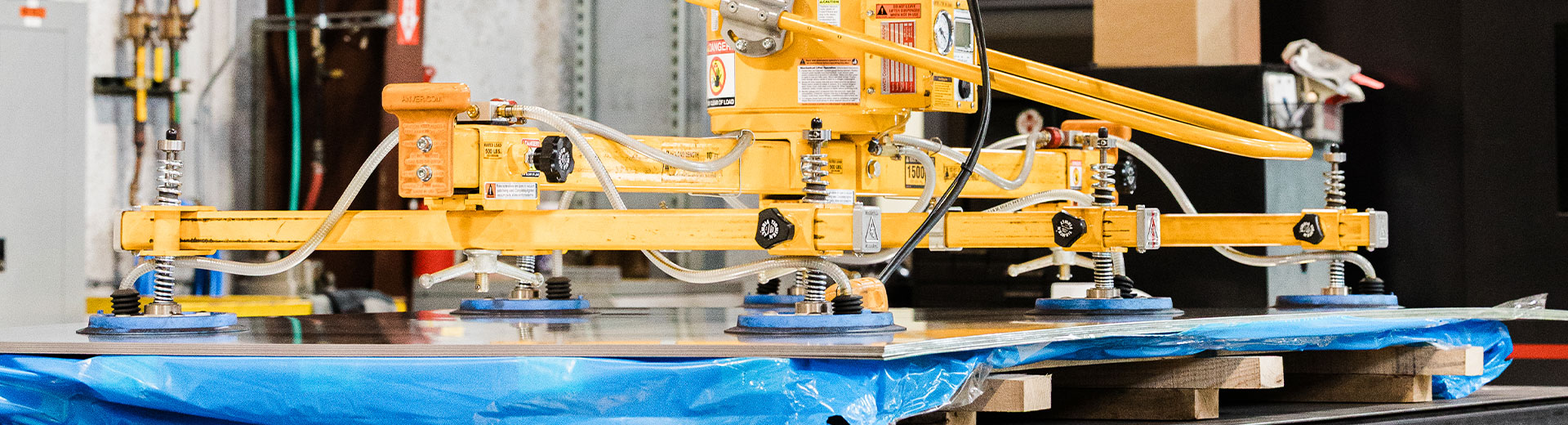

Lifts:

CAT GC70K-LP (15,000 lbs)

Clark CGC 70 (15,000 lbs)

CAT P5000-LP (4,500 lbs)

CAT GC 20 (4,000 lbs)

CAT GC25K (5,000 lbs)

Toyota 8FGU25 51hp (5,000 lbs)

Komatsu FG25T-16 54hp (5,000 lbs)

Cranes:

Shannahan Overhead (15 Ton)

(2) Overhead (7.5 Ton)

Overhead (5 Ton)

(10) Overhead (.5 – 2 Ton)

Trucking:

Freightliner with box trailer (44,000 lbs)

(2) 1 Ton Flatbed (6,000 lbs & 20,000 lbs with trailer)

¾ Ton (3,000 lbs)

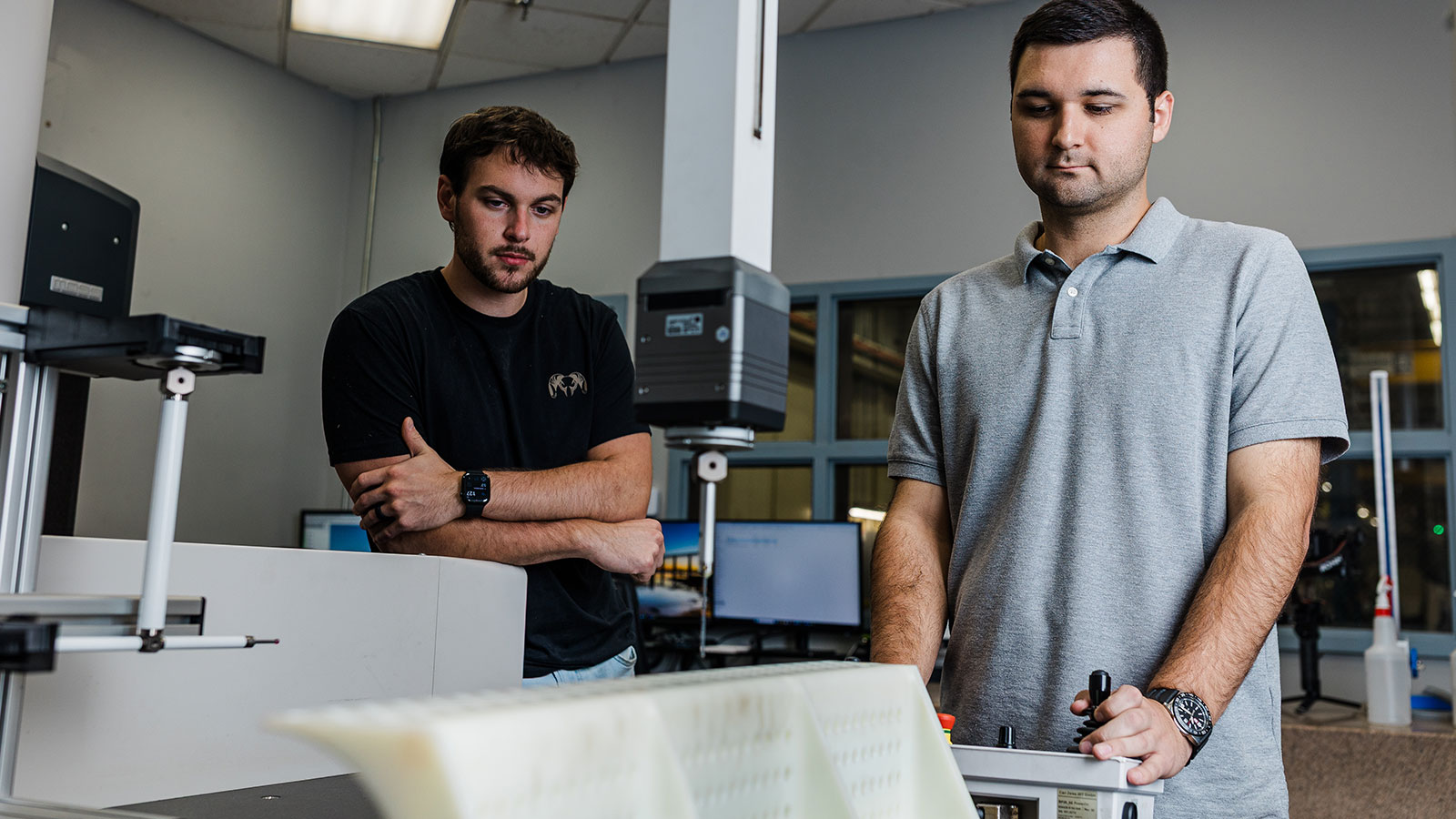

Quality Control/Reverse Engineering:

Zeiss Contura G2

6’ Faro Arm Edge-With 3D scanning

6’ Faro Arm Platinum

Starrett Optical Comparator

Starrett HB400 Optical Comparator

Zeiss Condura 6202

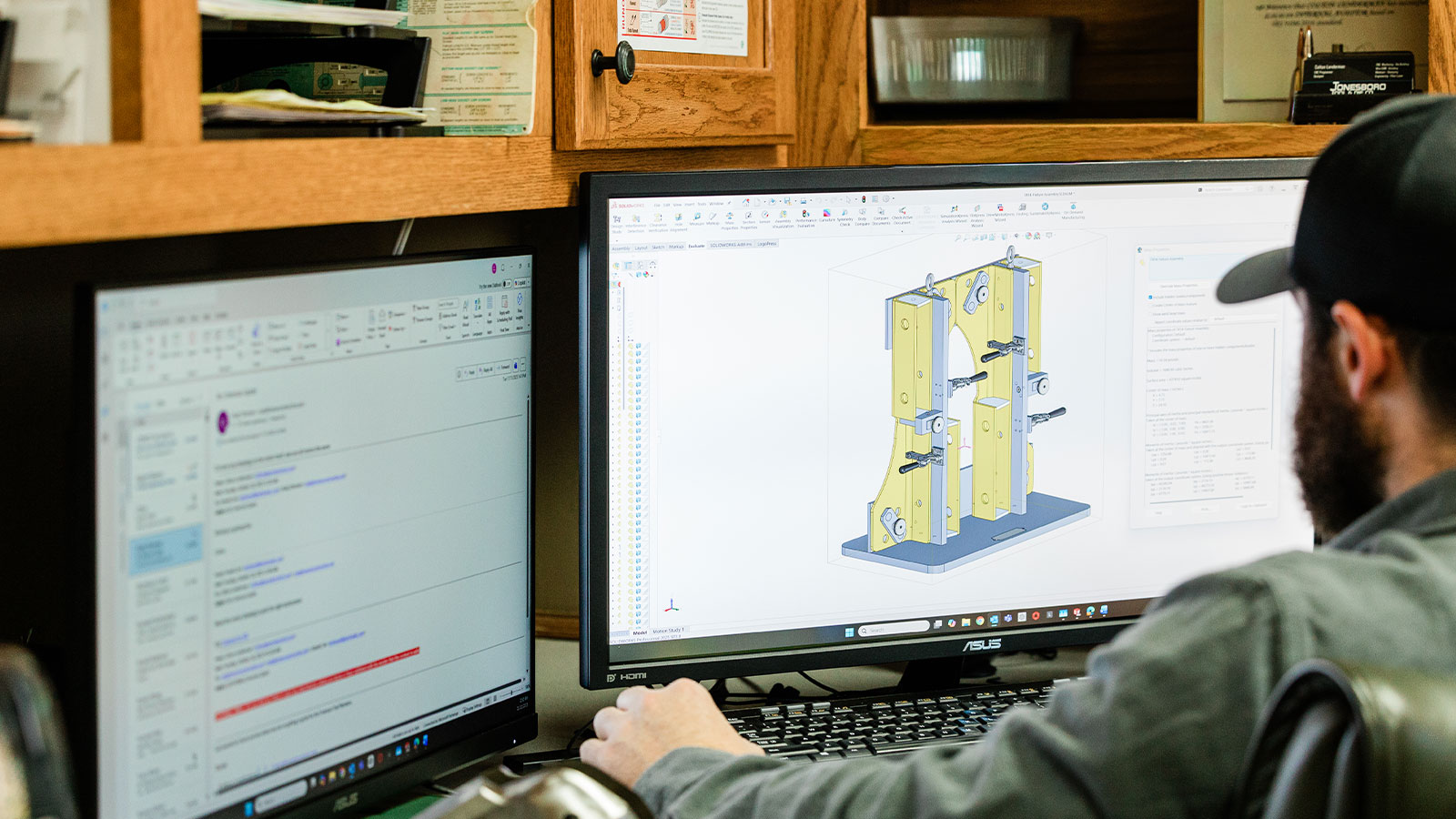

Computer Workstations:

(4) Engineering

(7) Programming

Software:

SolidWorks

Logopress

AutoCad

Esprit

PEP

Zeiss Calypso

Design X

Inventor

OMAX MAKE

JobBOSS²

ProgSim_X

Shipping:

Four loading/unloading bays for enclosed trailers.

Two pull through docks for flat beds.

Automated Tornado shrink wrapper.